In today's highly competitive business landscape, selecting reliable equipment is crucial for achieving operational efficiency and driving growth. According to a report by the International Data Corporation (IDC), organizations that invest in dependable technology can increase their productivity by up to 20% and reduce downtime significantly. This highlights the importance of choosing equipment that not only meets the current demands of the market but also adapts to future challenges.

Furthermore, a survey conducted by the National Association of Manufacturers (NAM) indicates that nearly 70% of manufacturers attribute their success to the effective utilization of reliable equipment. This reliance on dependable machinery and tools underscores the necessity for businesses to invest wisely. Navigating through various options can be overwhelming; however, understanding the key factors that contribute to the reliability of equipment — such as durability, customer reviews, and after-sales support — can help businesses make informed decisions. By prioritizing reliable equipment, organizations are better positioned to enhance their operational capabilities and ensure long-term success.

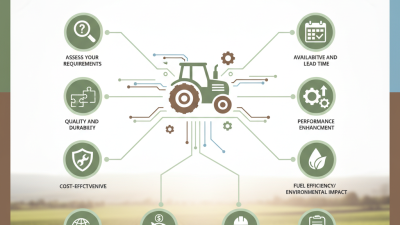

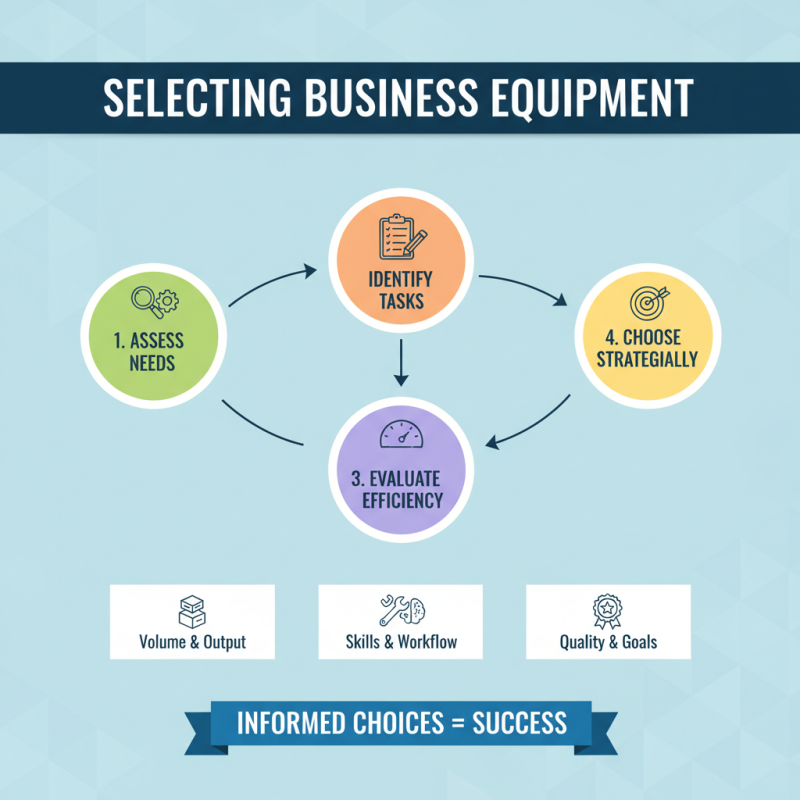

When selecting equipment for your business, understanding your specific needs is crucial to ensuring success. Begin by assessing the core operations of your business. Identify the tasks that require equipment and evaluate how each piece contributes to your overall efficiency and workflow. Consider factors such as the volume of work, the desired output quality, and the skills of your workforce. This foundational understanding will guide you in making informed choices that align with your strategic goals.

**Tips:** Create a checklist of your equipment requirements based on your business model. Include aspects like durability, maintenance needs, and the level of technology required. This list will serve as a reference point during your evaluation and help you narrow down your options effectively.

Another important consideration is scalability. As your business grows, your equipment needs may evolve. Opt for equipment that can adapt to changing demands without needing complete replacement. This foresight will save you time and money in the long run, allowing you to focus on scaling your operations instead of constantly upgrading your tools.

**Tips:** Research future trends in your industry to choose equipment that not only meets your current demands but is also compatible with emerging technologies. Engaging with industry experts or attending trade shows can provide insights into innovative features that may benefit your business in the future.

When selecting equipment for your business, understanding quality standards and certifications is crucial. According to a report by the International Organization for Standardization (ISO), over 1.6 million certifications were issued worldwide in 2022 alone, highlighting the importance of industry compliance and quality assurance. Certifications such as ISO 9001 (Quality Management System) and ISO 14001 (Environmental Management System) not only ensure that the equipment meets international safety and reliability standards but also demonstrate a commitment to continuous improvement and environmental responsibility.

Moreover, industry-specific certifications can significantly affect operational efficiency and product quality. For example, the American National Standards Institute (ANSI) indicates that businesses operating with certified equipment see an average improvement in productivity by 20%, directly impacting their bottom line. Additionally, equipment that adheres to these standards often includes rigorous testing and quality control measures, which can minimize potential downtimes and maintenance costs. In an environment where business reliability hinges on performance, choosing equipment backed by recognized quality certifications is not just beneficial but essential for sustaining competitive advantage.

When selecting equipment for your business, understanding the comparison between costs and long-term value is crucial. A study by the National Association of Manufacturers indicates that 45% of businesses struggle with equipment selection, primarily due to the high initial costs versus the expected lifespan and efficiency of the equipment. It’s essential to not only consider the upfront investment but also the potential operational savings over time. For instance, energy-efficient machinery may have a higher initial price, but according to the U.S. Department of Energy, businesses can save up to 30% on energy costs annually, significantly enhancing their long-term profitability.

Moreover, maintenance costs play a significant role in the overall expense associated with equipment. The Equipment Leasing and Finance Association reports that maintenance can account for up to 20% of total equipment costs. Therefore, investing in reliable equipment that requires less frequent repairs can mitigate unexpected expenditures and enhance operational uptime. Additionally, businesses should examine the total cost of ownership (TCO), which considers all associated costs, including installation, maintenance, and energy consumption. An insightful analysis can lead to a more informed decision that prioritizes sustainability and long-term viability, ensuring that equipment serves its purpose efficiently throughout its lifecycle.

| Equipment Type | Initial Cost ($) | Maintenance Cost (Annual) ($) | Expected Lifespan (Years) | Estimated Total Cost Over Lifespan ($) | Long-term Value Ratio |

|---|---|---|---|---|---|

| Industrial Printer | 5000 | 300 | 7 | 6200 | 0.81 |

| Construction Equipment | 25000 | 1500 | 10 | 41500 | 0.60 |

| CNC Machine | 15000 | 800 | 12 | 21300 | 0.70 |

| Refrigeration Unit | 8000 | 400 | 15 | 13600 | 0.59 |

| Packaging Machine | 20000 | 1000 | 8 | 28000 | 0.71 |

When selecting equipment for your business, the reputation of your suppliers plays a crucial role in determining your overall success. According to a report by the Institute for Supply Management, 75% of organizations find vendor reputation to be a significant consideration in the procurement process. A supplier with a solid track record not only assures you of quality products but also provides peace of mind regarding post-purchase support and warranty services. This is especially important in industries that rely heavily on equipment performance and reliability, such as manufacturing and logistics.

In addition to assessing supplier reputation, scrutinizing customer reviews can offer valuable insights into real-world equipment performance. A survey from the American Marketing Association found that nearly 80% of consumers trust online reviews as much as personal recommendations. Analyzing feedback from businesses similar to yours can help in understanding potential issues and gauge the consistency of the equipment’s performance. Moreover, utilizing platforms that aggregate reviews can reveal patterns in customer satisfaction and highlight any recurring problems, empowering businesses to make informed decisions about their investments.

When selecting reliable equipment for your business, it’s crucial to consider the maintenance and support services available. A well-defined support system can significantly enhance the longevity and performance of your equipment. Start by evaluating the manufacturer’s or supplier’s service offerings, where you should look for comprehensive maintenance contracts that include regular check-ups and emergency repairs. This not only ensures your equipment operates optimally but also minimizes downtime, which can be costly for your operations.

Moreover, investigate the availability of local service centers and the responsiveness of the support team. Quick access to service personnel can make a huge difference in resolving issues that may arise. It is beneficial to choose suppliers that provide detailed training for your team, ensuring that they are well-equipped to handle regular maintenance tasks and can quickly troubleshoot minor issues. Additionally, gather feedback from other businesses regarding their experiences with support services, as this can provide valuable insights into reliability and service quality.

Prioritizing these factors will help you choose equipment that not only meets your operational needs but also safeguards your business’s productivity in the long run.