In the realm of project development, selecting the appropriate equipment and parts is crucial to achieving both efficiency and quality. Renowned industry expert, Johnathan Mills, often emphasizes, "The right equipment and parts can make or break a project; it’s essential to consider not just functionality, but also compatibility and durability." This sentiment resonates with professionals across various sectors, highlighting the significance of making informed choices when it comes to tools and materials.

When embarking on a new project, the vast array of equipment and parts available can be overwhelming. From intricate components to heavy machinery, each element plays a vital role in the project's success. It is imperative to understand the specific requirements of your project, and to carefully evaluate how different parts and equipment will interact. The right selection not only enhances performance but can also lead to cost savings and reduced downtime.

In conclusion, careful consideration in choosing the right equipment and parts is a fundamental step in ensuring project success. By leveraging expert insights and undertaking thorough research, project managers can navigate the complexities of selection, ultimately leading to more effective and sustainable outcomes.

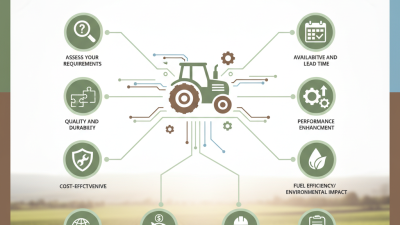

Understanding the requirements and specifications of your project is crucial for selecting the appropriate equipment and parts. Start by comprehensively defining the project's scope, including its goals, limitations, and the end result you wish to achieve. This initial assessment should cover factors such as the materials you'll be using, the environment in which the equipment will operate, and any specific performance benchmarks that must be met. Creating a detailed list of these requirements will serve as a guideline throughout the selection process, ensuring that you do not overlook critical aspects.

Once you have a clear understanding of your project specifications, consider the compatibility and integration of various components. It's essential to evaluate how different parts will work together and whether they align with your project goals. Look into the specifications of each piece of equipment, such as power output, size, and functionality, and compare them against your project's necessities. By meticulously matching equipment capabilities with project requirements, you can enhance overall efficiency, minimize potential issues, and ultimately lead to a more successful project outcome.

When embarking on a project, selecting the right equipment and parts is crucial for ensuring efficiency and success. One of the key factors to consider is the quality and reliability of the brands you are evaluating. According to a recent industry report by Market Research Future, approximately 70% of project delays can be attributed to equipment failure. Thus, investing in reliable brands can significantly reduce downtime and improve project timelines.

When assessing the quality of equipment brands, it's important to look for certifications and ratings. Many sectors rely on standardized testing procedures, such as ISO certifications, which indicate that the products meet specific quality management criteria. Furthermore, a survey conducted by the Equipment Leasing and Finance Foundation revealed that companies using high-reliability equipment see a 30% increase in overall productivity. This indicates that reliable brands not only enhance project performance but also contribute to long-term cost savings through reduced maintenance and replacement needs.

Additionally, consider user feedback and product reviews, as they provide valuable insights into the performance of equipment in real-world conditions. Research indicates that 85% of professionals rely on peer recommendations when selecting equipment, underscoring the importance of brand reputation in the operational landscape. By prioritizing quality and reliability when choosing equipment, project managers can enhance both the safety and effectiveness of their initiatives.

When embarking on a project, one of the key decisions revolves around choosing between budget-friendly and high-performance parts. Budget-friendly options typically allow for a greater initial investment in a project, enabling more flexibility in design and application. These parts may not always deliver top performance or longevity, but they can be adequate for tasks that don’t demand high levels of output. They also open the door for DIY enthusiasts or those with limited funds to engage in projects they might have otherwise considered too costly, thereby fostering creativity and innovation.

In contrast, high-performance parts are designed for efficiency and durability, often featuring advanced technology and robust materials that enhance their functionality. While the upfront costs are typically higher, these components can lead to savings in the long run, as they frequently require less maintenance and can deliver superior results over time. Choosing high-performance parts might be essential for projects that demand precision and reliability—such as professional applications or complex tasks—where failure could have significant consequences. Ultimately, understanding the specific needs of your project will guide you in weighing the benefits of cost savings against the potential advantages of investing in high-quality equipment and parts.

When embarking on a new project, selecting the appropriate equipment and parts is crucial for optimal performance. Beyond merely choosing the primary tools, understanding the essential accessories that enhance functionality can significantly impact your project's success. According to the International Society of Automation, equipment that is well-suited to its accessories can improve overall efficiency by up to 35%. This emphasizes the importance of identifying what's necessary to elevate your equipment's effectiveness.

To ensure you make the right choices, consider the specific requirements of your project. For example, if you're working with heavy machinery, accessories such as safety guards, alignment tools, and monitoring systems can significantly boost productivity and safety. Data from the Occupational Safety and Health Administration indicates that equipment with proper safety accessories reduces workplace incidents by as much as 50%. Therefore, it’s not only about how powerful your machinery is, but how well it is supported by the right adjuncts.

Tips: Before purchasing, conduct a thorough needs assessment to identify which accessories are vital for your project. This prevents overspending on unnecessary items and ensures that you invest in components that will truly add value. Additionally, seek insights from industry reports and user reviews to gauge the effectiveness of certain accessories. Engaging with professional forums or communities may also provide practical advice tailored to your specific equipment and project type.

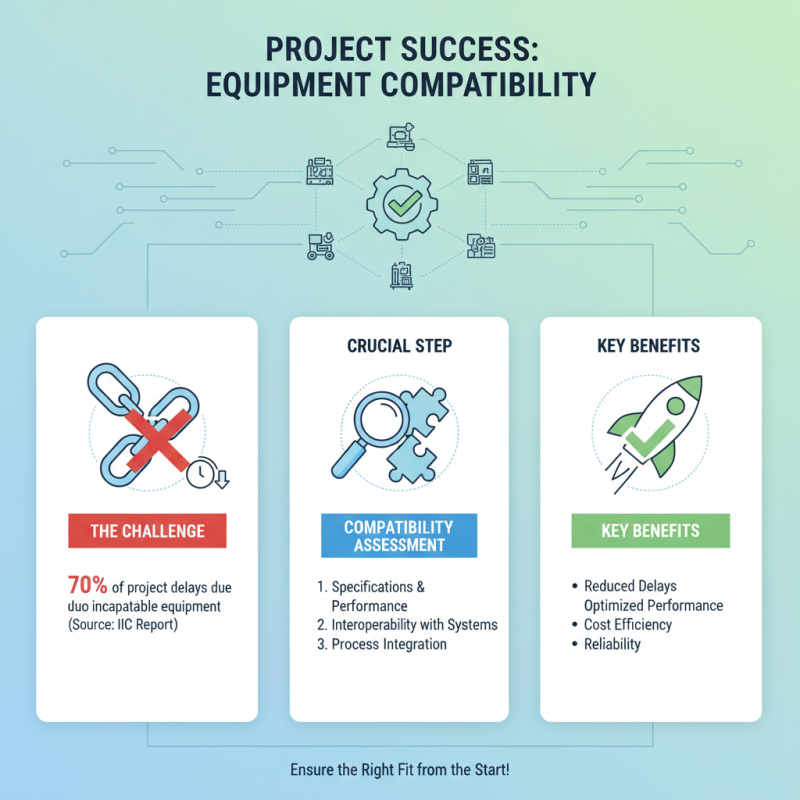

When embarking on a new project, ensuring compatibility between equipment and the specific project requirements is crucial for success. According to a report by the Industrial Internet Consortium (IIC), nearly 70% of project delays are attributed to the wrong choice of equipment or components, highlighting the importance of conducting a thorough compatibility assessment before making any procurement decisions. This assessment involves evaluating not just the specifications and performance metrics of potential equipment, but also their interoperability with existing systems and processes.

To achieve optimal compatibility, project managers should start by defining the key requirements of their project. A thorough analysis of necessary functionality, capacity, and environmental conditions can inform which equipment will best meet those needs. Industry data from the Project Management Institute (PMI) suggests that projects utilizing compatible equipment see a 25% higher chance of meeting their budget and timeline targets. Additionally, considering future scalability and flexibility can prevent costly retrofitting or replacements down the line, making thorough planning essential to aligning equipment with both current and future project demands.