The success of any agricultural operation heavily relies on the efficiency and reliability of its farm equipment. As harvest season approaches, the importance of timely farm equipment repair becomes increasingly evident. Farmers understand that machinery plays a pivotal role in ensuring that crops are harvested quickly and effectively. Well-maintained equipment not only enhances productivity but also minimizes downtime, allowing for a more seamless farming operation.

In this context, proactive maintenance and repair of farm equipment should not be overlooked. Regular inspections and timely repairs can prevent minor issues from escalating into major breakdowns, which could severely impact harvest timelines and overall yield. This article will delve into the critical nature of farm equipment repair, discussing how it directly correlates with maximizing harvest efficiency and ensuring that crops are brought in at their peak quality. By prioritizing maintenance and repairs, farmers can safeguard their investments and optimize their harvest outcomes.

Regular maintenance of farm equipment is crucial for ensuring optimal performance during the critical harvesting season. By adhering to a consistent maintenance schedule, farmers can identify and address potential issues before they escalate into costly repairs. Routine checks of key components such as engines, hydraulic systems, and belts can prevent unexpected breakdowns that could delay the harvesting process. This proactive approach not only saves time but also reduces the risk of yield loss, ensuring that crops are harvested at their peak.

Furthermore, well-maintained equipment operates more efficiently, which directly influences fuel consumption and labor costs. Regular maintenance tasks, such as oil changes, filter replacements, and calibration, help in maintaining equipment efficiency and extending its lifespan. This leads to significant economic benefits over time, as farmers can rely on their equipment to perform consistently during critical operational periods. Establishing a culture of regular maintenance ultimately fosters improved productivity and maximizes the overall efficiency of the farming operation.

| Equipment Type | Average Downtime (Days) | Repair Frequency (Times per Season) | Harvest Efficiency Impact (%) |

|---|---|---|---|

| Tractor | 3 | 5 | 30 |

| Combine Harvester | 5 | 4 | 45 |

| Plow | 2 | 6 | 20 |

| Seeder | 2 | 3 | 25 |

| Irrigation System | 4 | 2 | 15 |

Equipment downtime can significantly hinder harvest efficiency, leading to delays and potential losses. When machinery malfunctions or breaks down during critical harvesting periods, farmers face challenges that ripple through the entire operation. Every moment that equipment is idle translates to lost time that could otherwise be spent gathering crops at their peak ripeness. This disruption not only affects the quantity but also the quality of the harvest, as delays can lead to crops deteriorating or becoming more susceptible to disease.

Moreover, the financial implications of equipment downtime can be severe. Farmers often operate on tight schedules, and delays can result in increased operational costs and reduced income. The cost of repairing or replacing equipment can be substantial, but the cost of lost productivity and unsold produce can be even greater. By prioritizing timely maintenance and repairs, farmers can prevent breakdowns before they occur, ensuring that their equipment is always ready for the rigorous demands of the harvest season. This proactive approach not only enhances efficiency but also contributes to overall farm sustainability.

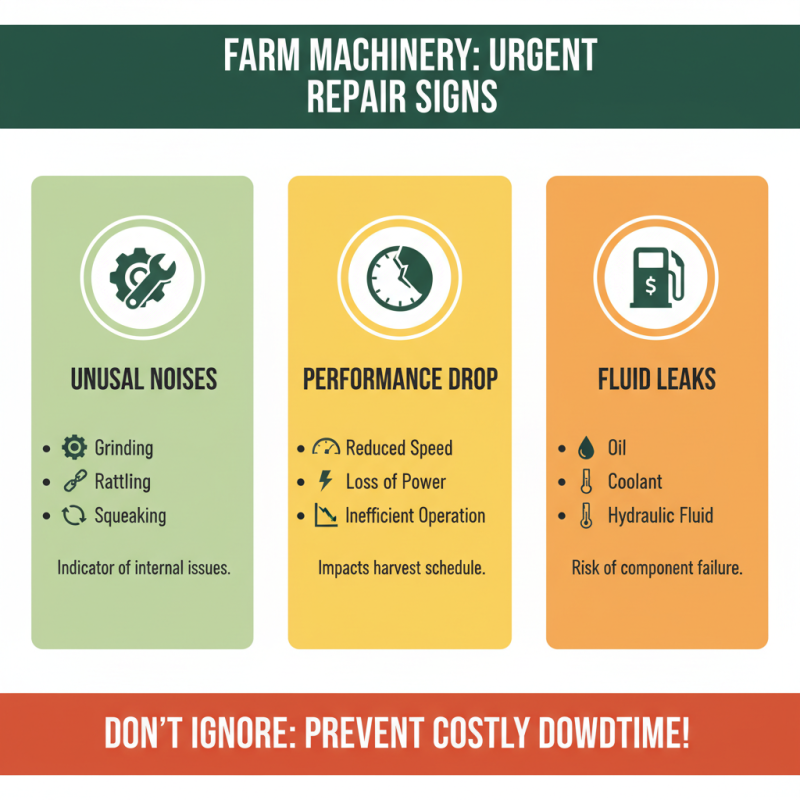

Recognizing the signs that your farm machinery requires urgent repair is crucial for maintaining operational efficiency during the critical harvest season. One of the most telling indicators is unusual noises coming from the equipment. If you hear grinding, rattling, or squeaking sounds, it is a clear sign that something may be wrong. Ignoring these noises can lead to more severe damage, resulting in costly repairs and downtime that can significantly impact harvest schedules.

Another critical sign to watch for is a decrease in performance. If your machinery is not operating at its usual speed or is struggling to handle tasks that it previously managed with ease, it may be time to investigate. This decline could be due to various issues, such as worn-out components or inefficient fuel usage, which not only affects productivity but can also increase operational costs. Regular maintenance and prompt repairs in response to these performance issues are essential to ensure that your equipment operates at peak efficiency, ultimately maximizing your harvest output.

Scheduling timely repairs during peak harvest seasons is crucial for maintaining workflow and ensuring that farmers can maximize their productivity. One effective practice is to establish a comprehensive maintenance calendar that aligns with the planting and harvesting cycles. By anticipating the busiest times of the year, farmers can proactively address potential equipment issues before they escalate into costly breakdowns. This approach not only minimizes downtime but also allows for more strategic planning of labor and resources.

Moreover, keeping a close communication line between operators and maintenance personnel can further enhance the repair scheduling process. Operators who are vigilant about the equipment's performance can report abnormalities early on, enabling timely intervention. Additionally, having a dedicated maintenance team on standby during peak periods can significantly reduce response times, ensuring that any necessary repairs are completed quickly without disrupting the overall harvest operation. Implementing these best practices can lead to smoother harvest seasons and greater overall efficiency in farm management.

Timely repairs of farm equipment play a crucial role in maximizing harvest efficiency, as they directly influence both cost management and yield quality. According to a report from the Agricultural Equipment Manufacturers Association (AEMA), downtime caused by equipment failure can result in an average loss of $1,150 per day for farmers. Regular maintenance and prompt repairs can significantly reduce the likelihood of such failures, ensuring that machinery operates at optimal efficiency. By addressing potential issues before they escalate, farmers can navigate planting and harvesting seasons more smoothly, thereby minimizing delays and associated costs.

Furthermore, the quality of the harvest is often determined by the health of the equipment used. Research published by the National Sustainable Agriculture Coalition indicates that properly maintained equipment can lead to a yield increase of up to 20%. Efficiently functioning machinery ensures that operations such as seeding, spraying, and harvesting are executed at the right time and with precision, directly impacting the productivity and quality of the crops. When equipment malfunctions, not only does it threaten operational timelines, but it can also result in a product that fails to meet market standards, further emphasizing the importance of timely repairs in maintaining both efficiency and quality in agricultural practices.