Choosing the right ag equipment parts is crucial for farmers and agricultural businesses. A recent industry report reveals that inefficient equipment can lead to a productivity decline of up to 25%. Therefore, selecting the right parts significantly impacts overall efficiency.

When evaluating ag equipment parts, consider compatibility, durability, and cost. Incompatibility may cause operational delays. Durable parts often reduce the frequency of replacements, hence saving money in the long run. Yet, some may opt for cheaper alternatives without considering long-term effects. This oversight can lead to further expenses and lost time.

Market research indicates that farmers prioritize quality over price when selecting equipment parts. They understand that reliable performance is non-negotiable. Ignoring quality can result in costly breakdowns. Ultimately, well-informed choices in ag equipment parts can enhance productivity and sustain agricultural operations effectively.

When selecting ag equipment parts, understanding your specific needs is crucial. Each piece of equipment has unique requirements based on its function and operating environment. Are you working with tractors or harvesters? Different machines demand different components. For instance, a plow has distinct parts compared to a combine. Knowing your machine can save time and money.

Consider the conditions in which your equipment operates. Dusty fields may require more durable filters. Wet conditions can affect tire selection. If you're unsure, take notes on your equipment's performance. What parts seem to wear out quickly? This observation can guide your selection process.

It's easy to get lost in a sea of options. Some parts might look compatible but aren't. Double-check specifications before purchasing. Sometimes, waiting for the right part is better than settling. You may end up with subpar performance if you rush. Keep exploring and learning about your equipment’s needs. Each decision shapes your efficiency in the field.

When selecting agricultural equipment parts, it's essential to consider compatibility. Ensure each part fits your specific machinery. Mismatched parts can lead to inefficiency and costly repairs. Take time to verify specifications. This may seem tedious, but overlooking details can result in significant downtime.

Quality is another key factor. Not all parts are created equal. Cheaper options may save money upfront but can lead to long-term issues. Invest in durable parts. They should withstand the rigors of daily use. Ask for recommendations or read reviews. Experience matters here.

Pay attention to the supplier's reputation. Not all suppliers provide reliable service. Research their history and customer feedback. A trusted supplier can guide you through your choices. Consider their after-sales support, too. Being left without assistance can be frustrating when issues arise. Choose wisely and be patient. The right parts can enhance your equipment's performance immensely.

When choosing ag equipment parts, evaluating compatibility is crucial. The right parts enhance performance and ensure safety. Start by checking the model numbers of your equipment. Match these numbers with the parts you consider. This simple step can save time and money in the long run.

Here are some tips. Research the specifications of the existing equipment. Understand what fits and what doesn’t. Don't rush into decisions. Sometimes, visually inspecting a part can reveal discrepancies you might overlook online. Pay attention to measurements, like bolt sizes or mounting points.

Compatibility goes beyond matching numbers. Consider how the part will perform in real-world conditions. Different materials and designs can impact durability. It’s worth reflecting on past experiences with parts that failed to mesh properly. Choose wisely to avoid issues down the road.

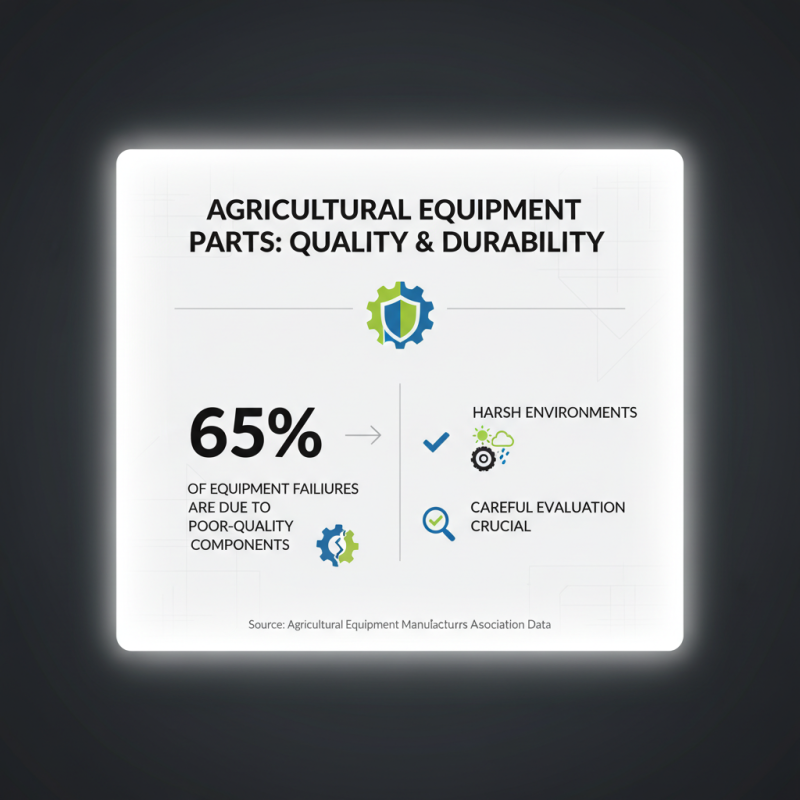

When selecting agricultural equipment parts, assessing quality and durability is crucial. The machinery in farming faces harsh environments every day. According to data from the Agricultural Equipment Manufacturers Association, about 65% of equipment failures can be traced back to poor-quality components. This emphasizes the need for a careful evaluation of the parts being chosen.

Durability is not solely about material strengths. It’s also about design and manufacturing processes. A report by the American Society of Agricultural and Biological Engineers suggests that well-designed components can last up to 40% longer. Look for parts with quality certifications or those recommended by industry experts. This can help minimize breakdowns and unexpected repair costs.

However, the perfect part doesn’t exist. Some may fit excellently but degrade quickly under stress. Others may be over-engineered, leading to unnecessary costs. Pay attention to user reviews and case studies. They often reveal the real-world performance of the parts. Reflecting on these insights can guide better decision-making.

When selecting agricultural equipment parts, budgeting plays a crucial role. Understanding your financial limits helps in making informed choices. Start by identifying the most essential parts you need. It’s easy to overspend if you don't have a clear list. Prices can vary significantly, so research is vital.

Consider the long-term versus short-term costs. Cheap parts may save money initially, but could lead to problems later. Investing in quality parts can reduce maintenance and replacement costs down the line. This approach often proves more economical over time.

Here’s a tip: always compare prices from multiple suppliers. A small difference in price can add up significantly, especially for bulk purchases. Don’t forget to account for shipping costs and potential import fees. Another recommendation is to keep an eye on seasonal sales. Timing your purchases may lead to significant savings. Remember, budgeting isn’t just about finding the lowest price; it's about value in the long term.