In today's world, equipment repair is a skill that is becoming increasingly valuable. DIY enthusiasts and professionals alike are often faced with equipment that needs fixing. Whether it's a broken lawn mower, a faulty kitchen appliance, or a worn-out power tool, knowing how to tackle these repairs can save money and time.

Mastering various repair techniques not only empowers individuals but also fosters creativity in problem-solving. For instance, understanding the inner workings of an item helps identify the root cause of issues. Not every repair will be straightforward. Some may require patience and multiple attempts. Mistakes are part of the learning process, leading to better methods for the next project.

Equipping oneself with the right tools and knowledge can make all the difference. Simple fixes can sometimes lead to revelations. However, there are moments when a repair may not go as planned. Reflecting on those instances provides valuable insights for future endeavors. Embracing these challenges contributes to personal growth and enhances one's skills in equipment repair.

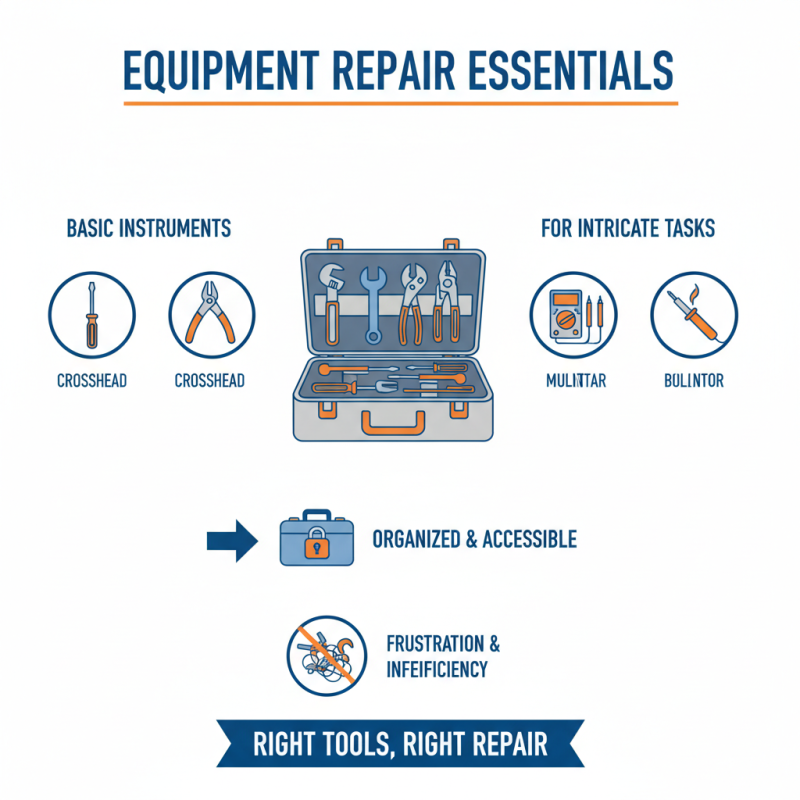

When it comes to equipment repair, having the right tools is essential. Screwdrivers, wrenches, and pliers are basic instruments that every DIY enthusiast should possess. For intricate tasks, a multimeter and a soldering iron can make all the difference. A solid toolbox helps keep these tools organized and accessible. When tools are scattered, it can lead to frustration and inefficiency.

Equally important are safety gear and protective equipment. Safety glasses shield your eyes from debris. Gloves protect your hands from sharp edges and chemicals. Many forget these simple measures, which can lead to costly mistakes or injuries. It's key to stay prepared, yet many often overlook this aspect. Regularly inspecting tools for wear and tear is another vital task. Rusty or broken tools can hinder progress and damage components.

Emotionally, repairs can be frustrating. It's easy to feel overwhelmed, especially with complex machinery. Taking a step back can help regain focus. Approaching repairs with patience often leads to better results. Remember, not everything will go as planned, and that’s okay. Embrace the learning process. Making mistakes is part of honing your skills as a repair enthusiast or professional.

Many DIY enthusiasts and professionals face common equipment issues. Identifying the problem early can save time and money. Start by listening for unusual sounds. A grinding noise might indicate a mechanical failure. Look for signs of wear and tear, such as frayed cords or leaking fluids. These indicators often lead to bigger problems if ignored.

Next, perform a visual inspection. Check bolts and screws for tightness. Loose parts can cause vibration, leading to further damage. Pay attention to the equipment’s performance. Is it slower than usual? Such changes could be a symptom of underlying issues.

Document your findings. Sometimes, it’s hard to see patterns without notes. A systematic approach can reveal frequent problems and provide insight into solutions.

Don’t overlook the importance of testing functionality. If equipment runs poorly after repairs, reassess your diagnosis. It’s common to miss subtle issues. A comprehensive understanding of how each component interacts is vital.

Encouragement can come from reviewing repair manuals or online resources, but hands-on experience offers the best learning opportunities. Embrace the imperfections in your journey as they lead to growth.

For DIY enthusiasts and professionals alike, mastering repair techniques can save time and money. Familiarizing yourself with various equipment types is essential. Start with tools like drills or lawn mowers. Understanding their mechanisms can make repairs smoother. Sometimes, disassembly can reveal surprises. A hidden screw may slow progress. Be prepared for quick adjustments.

When working on electronics, a multimeter becomes your best friend. Checking for faulty wires is crucial. A broken wire can cause the entire system to fail. Remember to handle small parts with care. They can be easily lost. It’s also helpful to take photos during disassembly. Those images guide you when reassembling.

In the realm of appliances, look for critical components like belts and motors. They commonly wear out over time. Take note of unusual noises or smells. They often indicate deeper issues. Not every attempt will be perfect. Reflection after each repair offers new insights. Each project enhances your skills and builds confidence. For every challenge faced, there is a lesson learned.

DIY repairs require strict safety protocols. A recent report from the Home Improvement Research Institute found that over 30% of home accidents occur during DIY projects. Proper safety measures can drastically reduce this risk. Always wear protective gear. This includes gloves, goggles, and masks when necessary.

Inspect your tools before use. Damaged tools lead to potential injuries. Make sure to operate them according to the provided guidelines. Ensure your workspace is well-lit. A clutter-free environment minimizes risks associated with tripping or accidents. Remember, safety is not just about tools; it’s also about personal awareness.

Tip: Always have a buddy system. If something goes wrong, having someone nearby can help. Furthermore, familiarize yourself with basic first aid. This knowledge can be invaluable in a crisis. Safety in DIY projects is not just recommended; it’s essential for every enthusiast. Prioritize your well-being to ensure a successful repair experience.

Equipment maintenance is crucial for both DIY enthusiasts and professionals. According to a report by the National Association of Home Builders, proper upkeep can extend the lifespan of tools by up to 30%. Regular cleaning is a simple yet effective technique. Removing dirt and grease helps equipment operate smoothly. It’s essential to use the right cleaning supplies. Sometimes, using household cleaners can lead to damage. Always check user manuals for guidelines.

Lubrication is another vital maintenance task. Many tools require lubricants to function properly. A study by the American National Standards Institute shows that well-lubricated machinery performs 20% more efficiently. However, over-lubricating can cause problems, which is often overlooked. Apply just enough to avoid buildup that can attract dirt. In addition, regular inspection of equipment parts is necessary. Look for signs of wear and tear. Replacing small components can prevent larger failures down the line.

Ignoring maintenance can be tempting when you’re busy. Many believe tools will last without effort. Yet, it’s often this mindset that leads to bigger issues. A recent report found that 40% of tool failures are due to neglect. Investing time in maintenance pays off. Small actions can lead to longer tool life and better performance. Being mindful of these simple practices can save money and frustration later on.